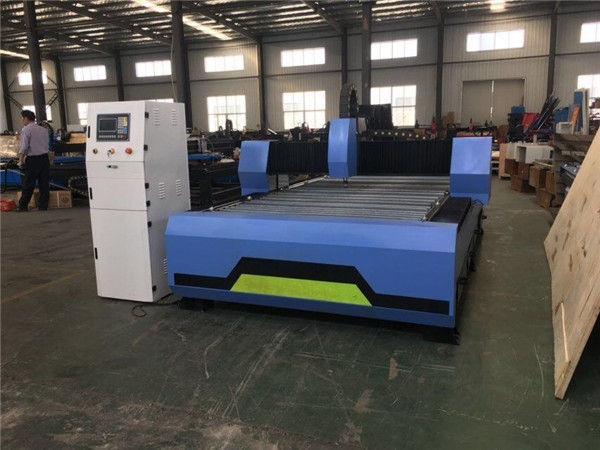

Mabilis na Mga Detalye

Kondisyon: Bago

Boltahe: 220

Na-rate na Lakas: 1000W

Dimensyon(L*W*H): 3305MM*780MM*2110

Timbang: 600KG

Sertipikasyon: ccc

Garantiyang: 1year

Ibinigay ang Serbisyo pagkatapos ng benta: Magagamit ang mga inhinyero sa makinarya ng serbisyo sa ibang bansa

tatak: nakeen

mode ng paggupit: plasma

kapal ng pagputol: 0.1-16mm

cnc o hindi: oo

lugar ng pagputol: 1300*2500

impormasyon ng file: USB

MOQ: 1SET

PACKING: PLYWOOD CASE

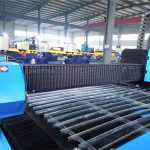

PAGPUTOL na materyal: metal .alloy metal .aluminyo

taas control: arc boltahe taas control at electric

Bentahe ng produkto

1.Bilateral drive, matatag na operasyon

2.High precision, magandang epekto

3. Taas ng boltahe ng arko (THC)

4.Maaaring i-install ang isang aparato sa pag-spray ng tubig, bawasan ang thermal deformation

5.Can cut carbon steel, hindi kinakalawang na asero, tanso, aluminyo at iba pang non-ferrous na mga metal

6. Simpleng operasyon at pagpapanatili at iba pa.

Mga tampok at pakinabang

1. Ihambing sa pagputol ng plasma, ito ay may mataas na precision cutting para sa iba't ibang uri ng mga metal na materyales, tulad ng pagputol ng hindi kinakalawang na asero, carbon steel, haluang metal na bakal, spring steel, aluminyo, tanso, pilak, titanium at iba pang mga metal na materyales na mas mababa sa 6 mm.

2. Ikumpara sa NC, na maaaring maputol ang anumang kumplikadong proseso at hugis. Walang ingay at hindi na kailangang magbukas ng anumang mga hulma.

3. Ihambing sa linear cutting, na may mas mabilis na bilis, 100 beses na mas mataas kaysa dito.

4. Dobleng lead turnilyo sa pagmamaneho, Maliit na init apektadong zone, magandang dimensyon katatagan. Flat at gwapong laser-slotted, nang walang susunod na proseso

5. Mataas na performance/price ratio: ang presyo ay 1/8 lamang ng katulad na CO2 laser cutting machine at 2/5 ng katumbas na NC Punch

6. Mababang gastos sa paggamit: USD2 lang kada oras na 1/8-1/10 ng katulad na CO2 laser cutting machine (USD22-USD35 kada oras)

7. Mababang gastos sa pagsubaybay sa pagpapanatili: 1/10-1/15 lamang ng katulad na CO2 laser cutting machine at 1/3-1/4 ang katumbas na NC Punch

8. Matatag na pagganap: bilang isang mature na laser apparatus, ang YAG laser cutting machine ay angkop para sa karamihan ng industriya ng pagmamanupaktura at pagproseso ng metal.

Mga parameter ng teknikal

| 1 | Pagputol ng hugis | anumang hugis |

| 2 | Sukat sa Pagpapakita ng LCD | 7.0Mga Susi |

| 3 | Epektibong Pagputol ng Lapad (X axis) | 1300mm |

| 4 | Epektibong haba ng pagputol (Y axis) | 2500mm |

| 5 | Haba ng Beam ng Linya | 1800mm |

| 6 | Haba ng Rail haba | 3000mm |

| 7 | Bilis ng Pagputol | 0-8000mm bawat minuto |

| 8 | Pagkakaputol ng Plasma | 2--20mm (Depende sa plasma power source capacity) |

| 9 | nakakataas ng katawan | 1set |

| 10 | Mode ng Pagmaneho | bilateral drive |

| 11 | Mode ng Pagputol | plasma |

| 12 | Aparato ng pag-iingat | Awtomatikong aparato ng pag-aapoy |

| 13 | Taas na aparato ng regulator | Ang taas ng boltahe ng arko |

| 14 | Paghahatid ng file | Paghahatid ng USB |

| 15 | Ang software ng nesting | Pamantayan ng Fastcam |

| 16 | Paghahatid ng file | USB |

| 17 | Sukat sa Pagpapakita ng LCD | 7" kulay |

| 18 | Pinagmulan ng Power ng Plasma | Hypertherm PowerMAX65 / 85/1650 o iba pa |

| 19 | Plasma Air | Pinindot lamang ang Air |

| 20 | Presyon ng Air na Plasma | Max. 0.8Mpa |

| 21 | Pagputol ng katumpakan | ± 0.5mm Pambansang pamantayang JB / T10045.3-99 |

| 22 | Kawastuhan ng kontrol | ± 0.01mm |

| 23 | Boltahe ng Power Supply / Dalas | 220V 50HZ |

| 24 | Na-rate na Power Supply | 1000W |

| 25 | Working temperatura | -10 ° C-60 ° C. Relatibong Humidity, 0-95%. |

Sistema ng kontrol at pagpapakilala ng software

Ang control system na ito ay binubuo ng pang-industriyang PC, center control card, controller display ng power supply, professional control software. Ang PC ay naka-install sa control box, ang center control card ay tumatanggap ng mga order mula sa software at isagawa ito. Sa pamamagitan ng controller display ng power supply, sinisindi namin ang mga Xe lamp, inaayos ang cutting parameters tulad ng current, frequency, pluse width accroding to different materials and plate thickness. At sa pamamagitan ng control software, ilalagay namin ang cutting file, idagdag ang lead line, ibigay ang kerf compensation, ayusin ang cutting position at iba pa.